Why Rear Enclosures Are Crucial for Miniature Speakers

2025-10-30

Speakers depend not only on their internal components but also on the acoustic environment in which they operate. For mini and micro speakers, the rear enclosure serves as a vital structural and acoustic element, directly influencing both sound quality and long-term durability. This article will discuss the crucial importance of rear enclosures in speakers and how to design with them in mind. However, understanding this relationship begins with the basic principles of speaker operation.

Speaker basics

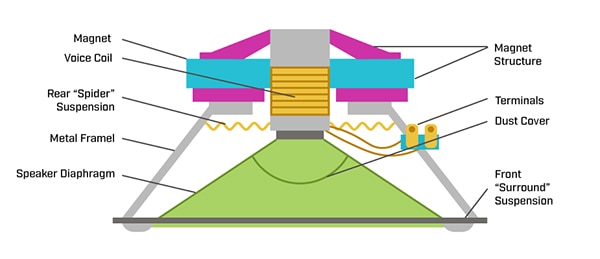

Fundamentally, all speakers share the same operating principle: a voice coil suspended within a magnetic field moves the diaphragm forward and backward, generating air pressure variations that we perceive as sound.

The difference lies primarily in scale. Larger, conventional speakers feature robust diaphragms and suspensions that are less impacted by minor changes in air pressure. On the other hand, mini and micro speakers use lighter, more flexible suspensions that respond significantly to enclosure characteristics. This makes enclosure design a key factor in achieving balanced performance. Overall, managing back pressure, maintaining diaphragm stability, and tuning frequency response are essential design considerations—not only for small transducers but also for high-precision larger speakers.

For a deeper dive into fundamental speaker concepts, refer to Same Sky’s article, The Complete Guide to Speaker Selection.

Figure 1: Basic structure of a speaker. (Image source: Same Sky)

Figure 1: Basic structure of a speaker. (Image source: Same Sky)

Understanding the rear enclosure

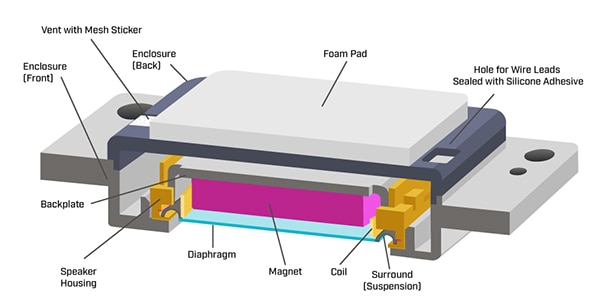

A rear enclosure is the cavity located behind the speaker that contains and manages the air displaced by diaphragm motion. In miniature speaker systems, this volume is a critical element affecting both acoustic behavior and mechanical integrity.

The enclosure generates back pressure that impacts the diaphragm’s movement, directly influencing frequency response and sound pressure level (SPL). While many small speakers see performance improvements with a properly designed rear cavity, certain miniature transducers are explicitly engineered to rely on one for correct operation. When this is the case, the rear enclosure is not merely a protective housing—it is an essential acoustic and structural component that defines system performance and stability.

In these configurations, the enclosure provides controlled back pressure that effectively acts as a mechanical spring, limiting diaphragm travel and safeguarding internal components.

This design strategy offers several benefits. By transferring part of the suspension function to the enclosure, engineers can create thinner, more compact speakers without compromising performance. These designs often exhibit higher acoustic efficiency for their size, extend low-frequency response compared to free-air counterparts, and allow precise tuning of frequency characteristics through enclosure volume adjustments.

However, operating such a speaker without its designated enclosure can lead to excessive diaphragm movement. This over excursion places stress on the surround, potentially causing stretching, deformation, or tearing, which results in premature failure. In addition to mechanical damage, performance suffers—output level decreases, frequency response narrows, and distortion increases.

Because these risks are especially pronounced in compact speakers with lightweight diaphragms and compliant suspensions, adhering to datasheet specifications for the rear enclosure is essential. Neglecting these requirements can lead to reliability issues, warranty claims, and costly redesigns.

Figure 2: Cross-section of a miniature speaker with front and rear enclosures. (Image source: Same Sky)

Figure 2: Cross-section of a miniature speaker with front and rear enclosures. (Image source: Same Sky)

Additional rear enclosure benefits

Not all speakers are designed to require a rear enclosure. Many mini, micro, and full-sized speakers are intended for free-air operation and can function effectively without one. However, incorporating an enclosure can still deliver significant acoustic and performance benefits.

For miniature speakers, a properly designed enclosure can enhance low-frequency response, smooth out frequency irregularities, and reduce distortion, allowing compact devices to produce sound quality beyond their physical size. For larger speakers, enclosures serve as powerful tuning tools, helping to control resonances, optimize acoustic output, and improve performance within limited mechanical spaces.

When engineers treat the enclosure as an active component—matching its volume to the diaphragm’s compliance, ensuring airtight seals, and choosing between sealed or vented configurations—they can substantially improve system efficiency and achieve more balanced audio output. Even when an enclosure is not mandatory, these design optimizations highlight why enclosure integration often leads to superior overall speaker performance.

Speaker enclosure design considerations

When a rear enclosure is required, proper integration is essential to meet the speaker’s intended performance targets. Begin by consulting the speaker’s datasheet, paying close attention to any “conditions” specified alongside the SPL parameter. If an enclosure is necessary, its recommended volume will typically be listed in cubic centimeters (cc). If no value is given, the speaker can operate without one, although adding an enclosure may still improve or fine-tune acoustic behavior.

As mentioned, enclosure volume has a direct influence on frequency response and SPL. A tolerance of ±10% is generally acceptable, but adhering as closely as possible to the specified volume ensures consistent and repeatable performance.

It is also critical to prototype and test the speaker with its intended enclosure in place. Evaluating performance in free air can produce misleading results and may overlook potential reliability issues. For best results, incorporate enclosure design early in development. Close coordination between mechanical and electrical design teams helps optimize acoustic output, maintain desired form factors, and align with manufacturing constraints.

For a rear enclosure to function correctly, the air volume behind the speaker must remain completely isolated from the front. Any unintended leaks reduce back pressure, diminish output, and alter the frequency response, undermining the acoustic role of the enclosure. To maintain separation, engineers commonly use gaskets, precision-fit housings, or adhesive seals. If vents are a part of the design, their dimensions, geometry, and placement must be tightly controlled to preserve predictable airflow and consistent acoustic performance. Whether the enclosure is sealed or vented, maintaining stable airflow is essential.

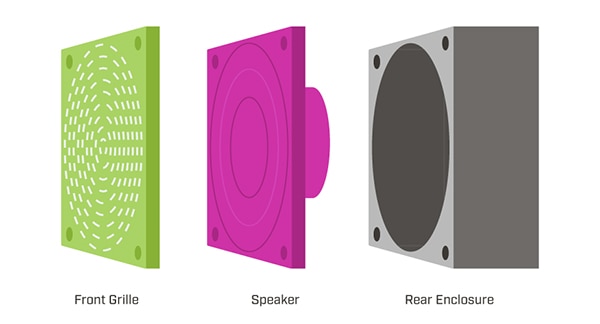

Lastly, the front grille should protect the diaphragm while minimizing acoustic obstruction. An open-area ratio of at least 20% is recommended to avoid noticeable sound loss, with 40% or greater preferred for performance-oriented applications. Adequate spacing between the diaphragm and grille must be maintained to prevent contact during peak excursion, considering both manufacturing tolerances and possible grille deflection. Using thinner materials and rounded perforations helps reduce airflow turbulence and distortion, contributing to cleaner sound reproduction.

Figure 3: A front grille and rear enclosure will benefit many speaker designs. (Image source: Same Sky)

Figure 3: A front grille and rear enclosure will benefit many speaker designs. (Image source: Same Sky)

Conclusion

Rear enclosures are fundamental to the performance, reliability, and service life of many miniature speaker systems. Whether they provide mechanical stability or serve as an acoustic tuning element, they must be regarded as integral components of the overall design rather than secondary considerations.

Recognizing when a rear enclosure is required—and engineering it to specification—helps prevent premature failures, ensures datasheet-level performance, and streamlines development. Careful adherence to enclosure volume, sealing integrity, and datasheet recommendations leads to consistent results from prototype through production.

For qualifying projects, Same Sky offers custom audio design, acoustic simulation, and rear enclosure development services. Their engineering team can assist in creating enclosures that satisfy both acoustic and mechanical integration requirements.

For designs where adding a separate enclosure is not practical, Same Sky also provides speakers with built-in rear enclosures. Explore these enclosed speaker options for simplified design integration. Or search their full selection of speakers from miniature to standard sizes.

Avertissement : les opinions, convictions et points de vue exprimés par les divers auteurs et/ou participants au forum sur ce site Web ne reflètent pas nécessairement ceux de DigiKey ni les politiques officielles de la société.